Galvanized steel pipe

In the production of Galvanized steel pipe in China, TOPREGAL is the leading manufacturer and supplier, consistently providing selected top Galvanized steel pipe at factory direct wholesale prices. Our Galvanized steel pipes make your building stronger and more durable. Selected high-quality materials, through strict inspection, to ensure reliable quality. Choose our Galvanized steel pipe, choose quality assurance, choose a stable future!

Why TOPREGAL Always Own Many Foreign Customers?

SANLI takes pride in the fact that our TOPREGAL steel products have earned prestigious international certifications such as IAF and CE.

We offer a diverse range of steel products to cater to the varying demands of our customers. Our extensive product line includes multiple specifications, ensuring that we can fulfill the unique requirements of different industries and applications.

Showing all 12 results

-

BS1387 Hot Dip Galvanized Steel Pipe Hot Rolled Round Galvanized Steel Pipe Galvanized Pipe

-

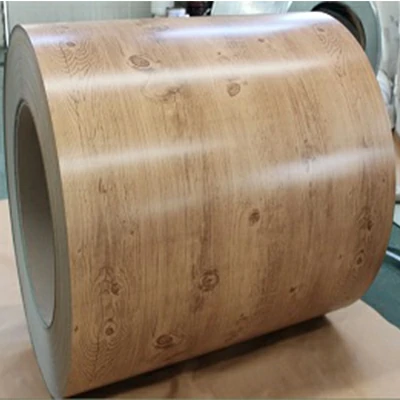

Galvanized Corrugated Board Steel Sheet Strip Coil

-

Galvanized Sheet Corrugated Board Strip Coil

-

Galvanized Steel Coil

-

Galvanized Steel Pipe

-

Galvanized Steel Pipe Round Hollow Sections ASTM JIS Standard

-

Hollow Section Black Annealing MS Square Steel Pipe

-

Pre Galvanized Square Steel Pipe

-

Q195 Q235 ERW Rectangular Tube Steel Square Tube Iron Pipe Price

-

Rectangular Steel Tube RHS SHS Carbon Welded Steel Pipe

-

RHS SHS Rectangular Tube Steel Square Tube Iron Pipe

-

Structural Sections Round Carbon Galvanized Steel Pipe

TOPREGAL is the supplier of advanced Galvanized steel pipe from Hebei Province, China. Our Galvanized steel pipe wholesale through precision production process to ensure reliable quality, durable. Whether used to support a building, deliver liquids or build a structure, our Galvanized steel pipes are built for the job. Our team can offer you the perfect price structure and provide powerful OEM functions. Whether you are building a large-scale project or manufacturing precision components, our Galvanized steel pipes provide you with reliable support.

Introduce About Galvanized Steel Pipes With Complete Production Methods

The surface of galvanized steel pipes is coated with a hot-dip or electroplated zinc layer. This will help the pipes to enhance its life during uses.Hot-dipped Galvanized Pipes Typically Involves Important methods of production:

- The steel surface needs to be thoroughly cleaned and free from impurities before the galvanizing process

- The steel coils are passed through a series of cleaning tanks, where they undergo alkaline cleaning and acid pickling. This step removes any rust, scale, or oil present on the surface.

- The steel coils are immersed in a fluxing tank. The fluxing solution helps to remove any remaining oxides and provides a protective layer on the surface of the steel.

- The cleaned and fluxed steel coils are then passed through a molten zinc bath at high temperatures (around 450-500°C). This process is called hot-dipping.

Galvanized Steel Pipes Benefits

- One of the main advantages of galvanized steel pipes is their excellent corrosion resistance.

- Another great thing about galvanized steel pipes is their durability. The zinc coating on the pipes adds an extra layer of strength and protection.

- Galvanized pipes are also known for their longevity. The zinc coating provides long-lasting protection to the underlying steel, extending the lifespan of the pipes.

- Additionally, galvanized steel pipes have a smooth interior surface, which allows for efficient and smooth flow of fluids.

Applications Of Galvanized Steel Pipes

- Hot-dip galvanized steel pipes are widely used in the manufacturing industry, including construction, machinery, coal mining, chemical, power, railway vehicles, automotive, highways, bridges, containers, sports facilities, agricultural machinery, oil machinery, mining machinery, greenhouse construction, and more.

- Galvanization increases the corrosion resistance of the steel pipes and extends their service life. Galvanized pipes have a wide range of applications:

- Not only these steel pipes with zinc coating being used as pipelines for water, gas, oil, and other low-pressure fluids,

- They are also used as oil well pipes and oil transportation pipes in the petroleum industry, particularly in offshore oil fields.

- Thirdly, hot dipped galvanized pipes are employed as oil heaters, condensers, and coal tar washing oil exchangers in the chemical coking equipment.

- Additionally, they are utilized as pipe piles for wharf construction, and as support structures in mining tunnels, among other applications.