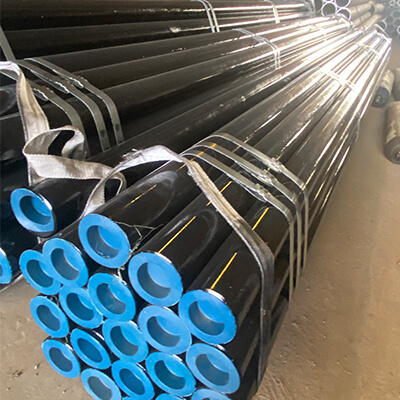

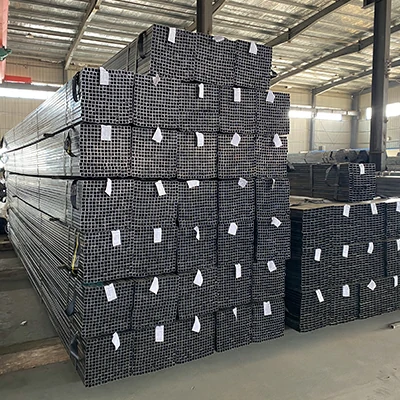

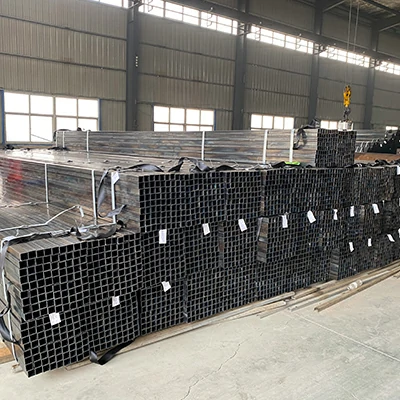

Welded steel pipe(round/square/rectangular)

Renowned as a distinguished wholesale and distributor of WELDED STEEL PIPES (ROUND/SQUARE/RECTANGULAR) in China, TOPREGAL exudes immense satisfaction in offering a diverse range of premium WELDED STEEL PIPES (ROUND/SQUARE/RECTANGULAR) at competitive wholesale rates. We have different kinds of products, our product quality is the best, we can constantly innovate reliable products, constantly innovate new products.

Welded steel pipes can be produced using common welding methods:

- Electric Resistance Welding (ERW): ERW involves passing an electric current through the edges of the steel plate or strip to generate heat.

- Submerged Arc Welding (SAW): SAW is a welding process that involves the formation of an arc between a continuously fed electrode and the workpiece.

- Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) Welding: GMAW, also known as MIG welding, uses a consumable electrode wire and a shielding gas to protect the weld pool from atmospheric gases.

- High-Frequency Induction Welding (HFIW): HFIW is a welding technique where high-frequency electrical currents are induced in the steel pipe to create heat.

Showing all 6 results

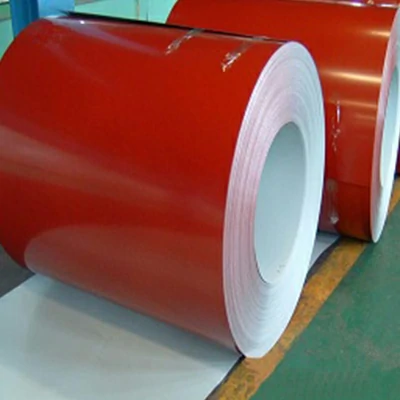

TOPREGAL as leading China Welded steel pipes manufacturer and supplier,in addition to direct sales, we also offer strong OEM capabilities for customers interested in private labeling,always provides quality steel pipes such as cold/hot rolling steel strips, 0.5-3.5 wall thickness high frequency welded steel pipes, furniture tubes, circular tubes, heterogeneous tubes, etc.

Welded Steel Pipe Provided By TOPREGAL

The most of welded steel pipes from TOPREGAL could match customers demand according its different shapes. Our welded pipes may cover wide range of shapes, such as Round or called circular for pressure piping, meanwhile, other shapes include rectangular, square, elliptical.

Differences Between Straight Seam Welded Pipes And Spiral Welded Pipes:

Construction:

Straight seam welded pipes are made by welding a long, continuous seam along the length of the pipe.

While, spiral welded pipes are made by helically winding a steel strip or plate and welding the edges together to form a continuous spiral seam.

Applications:

Straight seam welded pipes are commonly used in applications that require a high level of strength and are suitable for transporting fluids and gases under high pressure.

However, Spiral welded pipes are commonly used in applications that require larger diameters and are suitable for transporting fluids, gases, and solid materials.

TOPREGAL – These Are The Reasons Why We Can Win The Customers And Market

With over two decades of invaluable expertise in the steel industry, SANLI INDUSTRY CO., LTD has cemented its reputation as a prominent provider since founding in 1995. Accumulating more than 26 years of extensive experience, SANLI has emerged as a leader through its persistent dedication to quality steel production.

Driven by tenacity and knowledge gained throughout its rich history, SANLI continues pushing boundaries to give customers innovative solutions well into the future.

At SANLI, we have evolved into an integrated enterprise that encompasses the entire steel production process, from manufacturing and processing to trading and selling. Later, establishing exporting department – TOPREGAL.