Welding Schedule 80 galvanized steel pipes requires a combination of technical expertise, safety consciousness, and attention to detail. By following the step-by-step instructions, adhering to safety guidelines, and incorporating the provided tips, you can master the art of welding galvanized steel pipes and create robust and durable structures. Remember, practice and continuous learning are key to achieving welding excellence.

1. Understanding Schedule 80 Galvanized Corrugated Steel Pipes

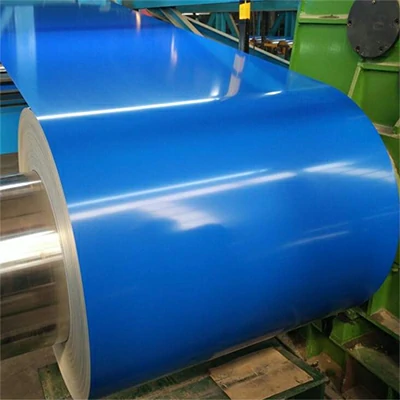

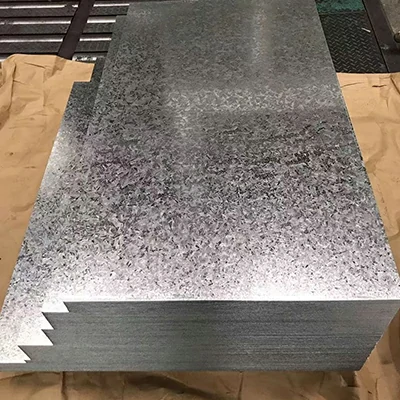

Schedule 80 galvanized corrugated steel pipes are a type of steel pipe that conforms to the specifications outlined in Schedule 80 of the American National Standards Institute (ANSI). These pipes through China Galvanized steel pipe supplier, are made from high-quality corrugated steel and undergo a galvanization process that coats them with a layer of zinc, enhancing their corrosion resistance and durability.

2. Pre-Welding Preparations

Before embarking on the welding process, thorough preparation is essential to ensure a successful and safe welding experience:

- Safety First: Prioritize safety by wearing appropriate protective gear, including welding helmets, gloves, and flame-resistant clothing.

- Clean the Pipe: Clean the surface of the pipe to remove any dirt, grease, or debris that may hinder the welding process.

- Galvanizing Removal: At the weld joint, remove the zinc coating using a wire brush or chemical stripper to expose the bare steel. This step is crucial for achieving a strong weld.

3. Welding Schedule 80 Galvanized Steel Pipes

Follow these step-by-step instructions to weld Schedule 80 galvanized steel pipes:

- Clamp the Pipes: Secure the pipes in place using welding clamps or a welding table to ensure stability during the welding process.

- Choose the Right Welding Process: Select the appropriate welding process based on your equipment and expertise. Common methods include arc welding, MIG welding, and TIG welding.

- Set the Welding Parameters: Adjust the welding machine’s settings according to the pipe thickness, type of welding process, and electrode selection.

- Start Welding: Begin welding by striking an arc at the joint and moving the welding torch along the seam, maintaining a consistent speed and angle.

- Control the Heat Input: Avoid excessive heat input, as this can damage the zinc coating and weaken the weld.

- Post-Weld Cleaning: After welding, clean the weld area to remove any slag or spatter.

4. Safety Considerations

Welding galvanized steel pipes by steel pipe manufacturers, requires special attention to safety:

- Fume Control: Ensure adequate ventilation or use a fume extractor to remove harmful fumes generated during welding.

- Fire Prevention: Keep a fire extinguisher nearby and be cautious of any flammable materials in the vicinity.

- Electrical Safety: Follow electrical safety guidelines and ensure proper grounding of the welding equipment.

5. Tips for Achieving High-Quality Welds

Here are some tips to enhance the quality of your welds:

- Practice: Gain experience by practicing on scrap metal before welding actual pipes.

- Proper Electrode Selection: Choose electrodes specifically designed for welding galvanized steel.

- Maintain a Steady Hand: Keep your hand steady while welding to ensure a consistent weld bead.

- Visual Inspection: Regularly inspect the weld for any defects or inconsistencies.