The hot rolled steel coil is a type of steel coil, it has wide range of applications and good versatility. For these features, many industries and manufacturers are favor it. In this article, as one of the leading steel coil manufacturers we will introduce the hot rolled steel coil detailly to you.

The making production of the hot rolled steel coil

Raw Materials

Usually, to ensure the ultimate quality of hot rolled steel coil, our company will choose the high-quality iron ore to do the raw material. And then we will refine the iron ore in a blast furnace to make it be the iron. Of course, Scrap steel and other alloying elements may also can composite the desired chemical composition. This feature makes the process of production of hot rolled steel coil can save many materials.

Steelmaking

In the steelmaking process, the worker will send the raw materials into a furnace to melt and to produce molten steel further. There have two methods the workers usually use. In addition, our company always add alloying elements during the steelmaking to adjust the composition of the steel. But you may ask if the alloy will impact the quality of the hot rolled sheet coil? On the contrary, the elements of the alloy can increase the quality of the hot rolled steel coil.

Continuous Casting

After steelmaking, the molten steel is cast into semi-finished shapes. In this process, the molten steel is poured into a water-cooled mold, where it solidifies into a semi-finished product.

Reheating

In this step, the semi-finished slabs or billets will be heated to high temperatures in a furnace in preparation for hot rolling. This process can ensure that the steel is malleable and it can be formed into coils.

Hot Rolling

The reheated slabs or billets are fed into a series of rolling mills. In this rolling, they will be are thinner and longer strips of steel under the rolling. The hot rolling process involves passing the steel through a series of rollers at high temperatures to reduce the thickness and achieve the desired dimensions.

To achieve the desired thickness and shape which accord our customer need, the steel may undergo multiple passes. The specific frequency be decided by the specific demands.

Coiling

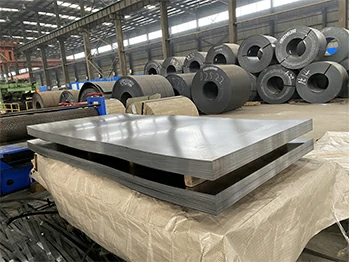

When the steel has been hot rolled to the desired thickness, it will be coiled into large rolls or coils by a coiling machine.

Finishing

After cooling, the hot rolled steel coils will undergo additional processing steps such as pickling, oiling, or leveling. Through these steps, the surface quality and flatness of the hot rolled steel coil can be improved highly. The beautiful surface also is a judgement standard of the quality of the hot rolled steel coil.

Quality Control

Throughout the production process, our worker will implement the quality control measures to ensure that the hot rolled steel can meet the required specifications. Except this way, we will do random inspection to our hot rolled steel. Based on these methods, our company has supplied the high-quality steel products over 15 years for oversea customers.

Storage and Shipment

Once the hot rolled steel coils have passed quality inspection. We will store them in a clean and dry warehouse to keep the quality of these hot rolled steel coil. When the customers need them, we can quickly deliver the high-quality hot rolled steel coil.

The advantage of the hot rolled steel coil

Improved Workability

The hot rolled steel coil is malleable and ductile, this feature makes the hot rolled steel coil is more suitable for construction and manufacturing. If you are looking forward a kind of coil sheet which has extensive fabrication and bending, the hot rolled steel coil is a good choice for you.

Higher Strength

Of course, as the customers we certainly want the material we used have the higher strength to satisfy our demand. The hot rolled steel coil typically has higher strength and toughness compared to cold rolled steel. In addition, the above hot rolling process can improve the mechanical properties of the steel.

Suitability for High-Temperature Applications

In many industries, the elements would work in the high temperature, then we can make these elements by hot rolled steel coil. Because the hot rolled steel coil can retains its strength and integrity at high temperatures.

Except the hot rolled steel coil, there also have other coils such as the stainless steel coil. The stainless steel coil have a batter ability of the anti-corrosion than the hot rolled steel coil. Except the sheet coil, our company also is a good China steel pipe manufacturer. Our company will make the pipes use the sheet coil made by ourselves.