product

Product Details

Features

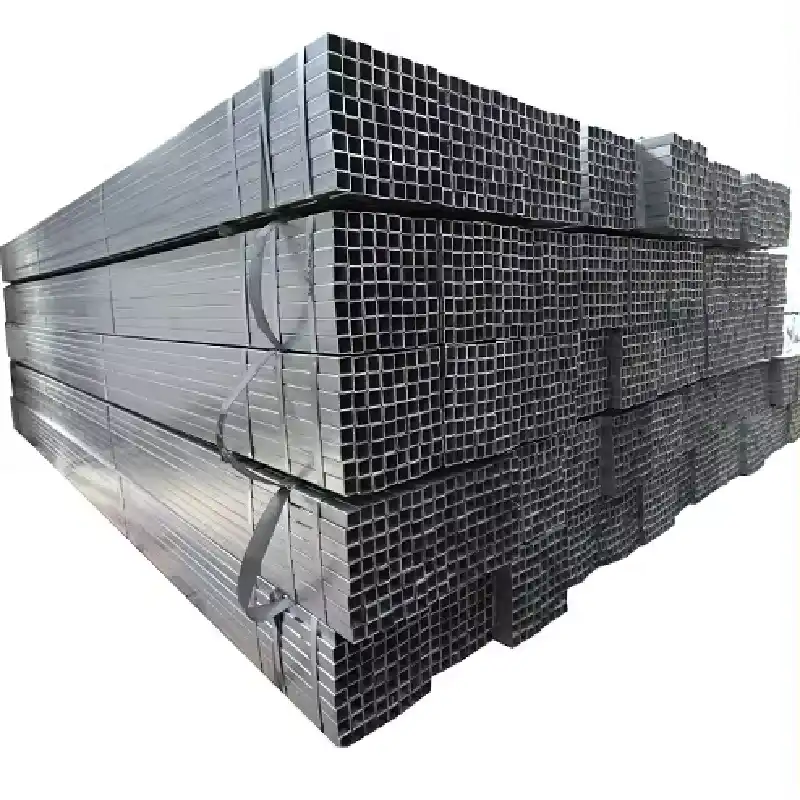

2. Durability: Due to its seamless construction and thicker wall, this type of pipe exhibits outstanding durability, making it suitable for use in demanding industrial applications.

3. Corrosion Resistance: Schedule 80 Seamless Pipe is often made from corrosion-resistant materials such as stainless steel or alloy steel, further enhancing its longevity and suitability for corrosive environments.

4. Versatility: While commonly used in high-pressure systems such as oil and gas pipelines, Schedule 80 Seamless Pipe finds applications in various industries, including chemical processing, power generation, and manufacturing.

5. Precision Engineering: The manufacturing process of seamless pipes involves precision engineering techniques, ensuring uniformity in dimensions and superior mechanical properties.

Advantages

1. Enhanced Strength: With its thicker wall construction, Schedule 80 Seamless Pipe offers superior strength compared to standard pipes, ensuring reliable performance in high-pressure environments.

2. Reduced Risk of Leaks: The seamless design eliminates the risk of leaks that can occur at welded seams, providing a more reliable and secure piping solution.

3. Longevity: Schedule 80 Seamless Pipe’s durability and corrosion resistance contribute to its extended lifespan, reducing maintenance requirements and lifecycle costs.

4. Versatile Compatibility: This type of pipe is compatible with various joining methods, including welding, threading, and flanging, offering flexibility in installation and system design.

Why choose us

A Schedule 80 seamless pipe manufacturer is a company that specializes in producing high-quality seamless pipes conforming to Schedule 80 specifications. Schedule 80 refers to the wall thickness of the pipe, indicating a thicker and stronger pipe compared to Schedule 40 for higher pressure and temperature applications. As a manufacturer of Schedule 80 seamless pipes, we use advanced manufacturing processes to manufacture seamless pipes without any welds, thereby improving the strength, integrity and leakage resistance of the product.

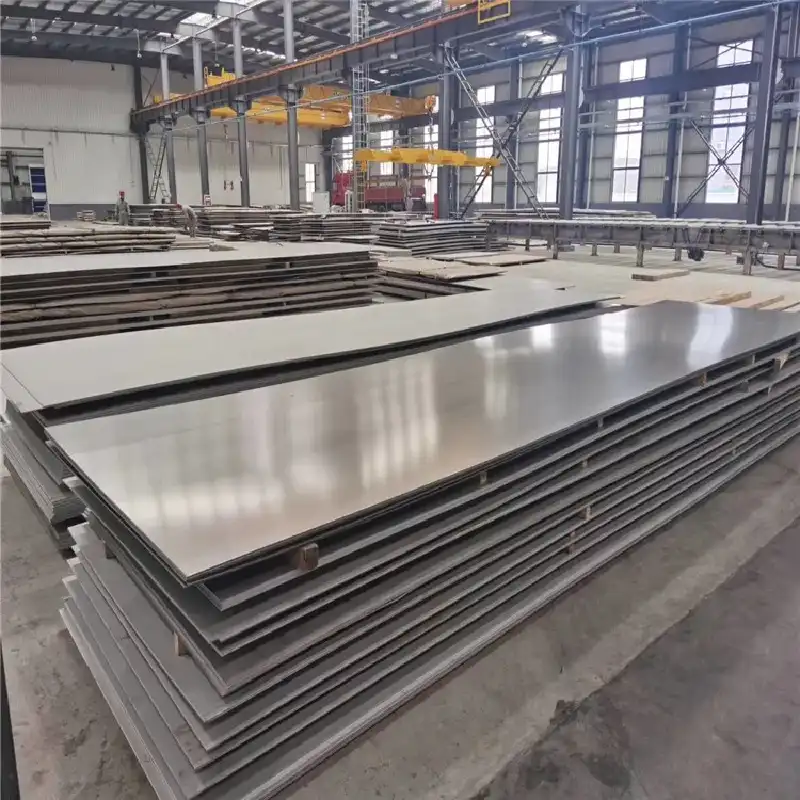

Our factory

Topregal (Tianjin) Industrial Co Ltd, strategically located in Tianjin, China, stands as a beacon of quality and reliability in the steel industry.The company’s extensive experience in the global steel market has enabled it to develop a keen understanding of the intricate needs of its clients. Topregal’s sister company, Real Team Industrial Limited, shares the same commitment to excellence, ensuring that clients receive the highest quality of service. Together, these entities form a formidable alliance, equipped with professional sales teams, dedicated purchase teams, meticulous quality control teams, and responsive after-sales service teams. This comprehensive approach guarantees that every client enjoys a satisfying order purchasing experience.

Applications

1. Durability: Due to its seamless construction and thicker wall, this type of pipe exhibits outstanding durability, making it suitable for use in demanding industrial applications.

2. Corrosion Resistance: Schedule 80 Seamless Pipe is often made from corrosion-resistant materials such as stainless steel or alloy steel, further enhancing its longevity and suitability for corrosive environments.

3. Versatility: While commonly used in high-pressure systems such as oil and gas pipelines, Schedule 80 Seamless Pipe finds applications in various industries, including chemical processing, power generation, and manufacturing.

If you are interested in our products, please contact us !