The profile steel is the steel which has various cross-sectional shapes. They have a wide range usage in the industries such as the construction, manufacturing, and engineering applications. Of course, the wide range of the profile steel is based on the various shapes of the profile steels.

And then I will introduce the different kinds of profile steel.

I-Beams: we can know its shape by its name. Its character is the I-shaped cross-section. Due to this special shape, it has the good ability of load-bearing in the vertical and horizontal directions. Usually, in the construction of the buildings and bridges need it.

H-Beams: it is similar to I-beams, but it has more equal flange widths and thicknesses. For this reason, it can supply the better weight distribution and resistance to torsion.

T-Sections: it can be seen from its name too. It is like to the letter T. Thanks to this shape, it can play a vital role in the place which need one-way strength, such as bridge construction or as girts in building frames.

Z-Sections: the Z-shaped has a shape like the letter Z. it is usually can act as purlins, bracings and supports due to their unique shape. The shape of letter Z can resists buckling under load.

Box Sections: these are hollow profiles which can play their role in columns, beams, and architectural features. Usually, these places need a profile steel which has a good combination of strength and reduced weight.

Round Tubes/Pipes: it primarily used in fluid transportation or as structural elements requiring circular profiles.

Angles: the angle has a L-shaped. And the shape decides the angles can connect and brace other members. So, many workers use them as the brackets, trusses, and reinforcement,

Channels: usually, the channel has two types, the one is the u channel steel, the other one is c channel steel. The different shapes can provide the different load-bearing characteristics and installation requirements.

The China u channel steel detail information

We have known that the u channel steel is one of the profile steels, and we also need know that the u channel steel features a symmetrical shape with two parallel flanges, and the two parallel flanges are connected by a web in the middle. The special way of connection gives the u channel steel the shape like the letter U. Its length can be adjusted accord the specific requirements, so there no have a specific demand of its length. Of course, its cross-sectional dimensions also can be customized. All of these random change for meeting specific load-bearing and structural requirements prepare. It can be used to make the high performance u channel pipe.

The manufacturing process of the China u channel steel

The Hot Rolling

In hot rolling process, steel billets or ingots are heated to high temperatures and then them are passed through a series of rolling mills to shape them into the desired U-channel profile.

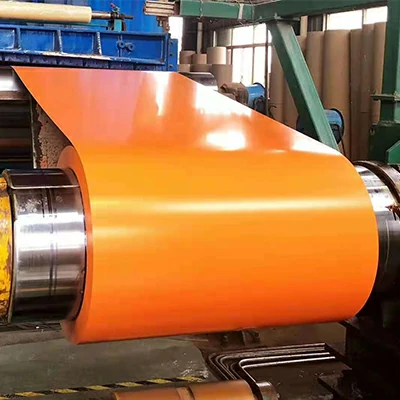

The Cold Forming

Cold-formed U-channel steel is produced by bending or folding flat steel strips or coils into the desired U-shape using press brakes or roll forming machines.

The advantages of the hot rolling

This process can provide high-quality structural steel which has the excellent mechanical properties.

The advantages of the cold forming

The cold forming can make the steel in a tighter dimensional tolerance, and it is suitable to produce u channel steel with thinner wall thicknesses.

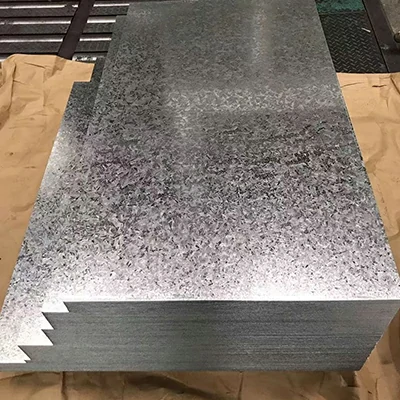

And to enhance the corrosion resistance and durability ability of u channel steel, our factory will surface coat or galvanize the u channel steel.

Although our company is one of the super China steel pipe manufacturers, we also sale the China steel u channel.