Emblematic of the highest standards in manufacturing, galvanized steel pipes from esteemed steel pipe producers have solidified their status as an indispensable component across a multitude of industries. This widespread adoption is largely attributed to their exceptional durability and unparalleled resistance to corrosion. The robust properties inherent in these pipes have rendered them a trusted choice for applications where resilience and longevity are paramount. Through meticulous craftsmanship and innovative production techniques, these steel pipes exhibit an enhanced defense against the erosive forces of time and environment, thereby affirming their ubiquitous presence within diverse industrial sectors.

How Strong Is 314 Galvanized Pipe

Its durability and fortitude are chiefly measured through two critical performance indicators: yield strength and tensile strength.Yield strength, a testament to the pipe’s structural integrity, represents the threshold point where the material initiates permanent deformation without succumbing to fracture. This characteristic ensures that the 314 galvanized pipe maintains its form under considerable stress, bending but not breaking.

With a superior tensile strength, the 314 galvanized steel pipe is designed to withstand formidable forces, showcasing its unparalleled ability to resist breakage even under extreme pressure conditions.

How Strong Is Galvanized Steel

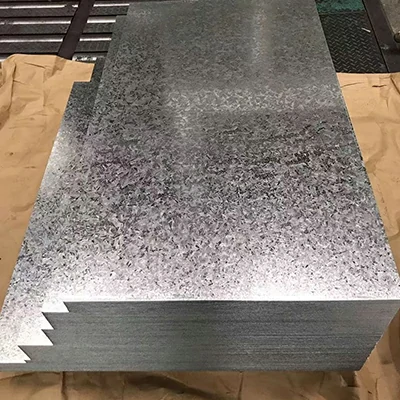

Galvanized steel inherently harnesses the inherent resilience of its core steel material and fortifies it further with an additional protective barrier in the form of a zinc coating. This meticulous galvanization process amplifies the pipe’s resistance to both corrosion and wear, thus augmenting its overall durability and extending its lifespan significantly. Although the precise strength parameters may fluctuate contingent upon the grade of steel employed and the thickness of the zinc coating, galvanized steel consistently demonstrates remarkable hardness and exceptional load-bearing capabilities.Its remarkable resilience against impact and steadfast stability under duress serve as a compelling testament to its exceptional strength, especially in the face of challenging and inhospitable environments.

Corrosion resistance of Galvanized Steel: Galvanized process formed a layer of zinc protective film on the surface of the steel, the zinc layer can effectively isolate the contact between air and water and the steel.

Long service life of Galvanized Steel: With excellent corrosion resistance, the service life of galvanized steel products is significantly longer than that of ungalvanized steel.

Galvanized Steel processing performance is good: galvanized steel in the cutting, bending, welding and other secondary processing, the surface of the zinc layer will not affect the basic processing performance, and in most cases, the zinc layer to a certain extent can also play a protective role.

Galvanized Steel is widely used: Galvanized steel is suitable for various application scenarios.

How Is Galvanized Steel Pipe Measured

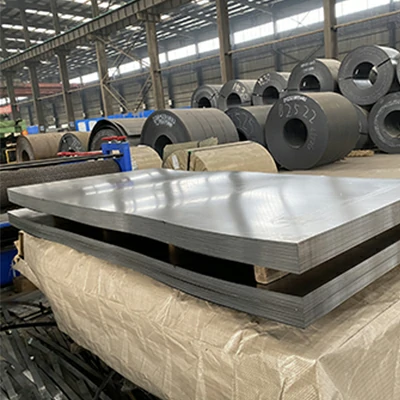

Galvanized steel pipe is robustness and operational capabilities are meticulously evaluated through a multitude of critical parameters. Paramount among these are the pipe’s diameter, expressed either in inches or millimeters, which determines its overall size. The wall thickness is another significant factor, gauged either in terms of standard measurement units or millimeters; this directly influences the pipe’s solidity and, by extension, its inherent strength. Furthermore, the weight per linear foot serves as an indirect yet powerful indicator of the pipe’s thickness and consequent resilience.

Galvanized steel pipe product parameter:

| Commodity | Galvanized Steel Pipe |

| Material | Q195 |

| Standard | GB, JIS |

| Thickness | 0.12mm -3.0mm |

| Width | 15-870mm |

| Surface | zinc coating |

| Technique | Cold Rolled with galvanized |

In addition to these dimensional attributes, comprehensive mechanical testing further substantiates the pipes strength and malleability. Tensile tests, for instance, rigorously assess the pipe’s resistance to breaking under tension, while hardness tests delve into its durability and resistance to surface indentation. Bend tests, on the other hand, evaluate the pipe’s pliability and ability to withstand deformation without fracturing. Collectively, these empirical assessments provide a profound insight into the pipe’s overall structural integrity and its potential for withstanding various stress conditions, thereby affirming its superior strength and ductility.

What Is Galvanized Steel Pipe Used For In Plumbing?

Galvanized steel pipes hold a pivotal position within plumbing systems, leveraging their innate robustness and dependability. These pipes are ubiquitously employed across an array of applications, including the conveyance of potable water, management of waste drainage systems, operation of heating and cooling mechanisms, as well as the intricate network of fire sprinklers. The transformative galvanization procedure serves as an impermeable shield against both interior and exterior corrosion, thereby effectively mitigating the risks of leaks and contamination over the course of their service life.

The exceptional durability of galvanized steel renders it capable of withstanding intense pressures and soaring temperatures, thereby positioning it as the optimal choice for demanding industrial plumbing systems. Nevertheless, it is noteworthy that while galvanized steel boasts such robust qualities, there has been a growing trend in residential plumbing towards the use of PVC and copper. This shift is primarily driven by their simplified installation process and the significantly reduced likelihood of corrosion over an extended period.

Expertly crafted by seasoned steel pipe manufacturers, galvanized steel pipes boast an exceptional blend of strength and versatility that sets them apart in a myriad of applications. The 314-grade galvanized pipe serves as a shining testament to this robustness, making it crucial to comprehend the metrics by which its strength is gauged for accurate selection and deployment. Despite the emergence of alternative materials in specific sectors of the market, galvanized steel pipe maintains its status as a durable and reliable option in plumbing contexts, steadfastly proving its enduring value.