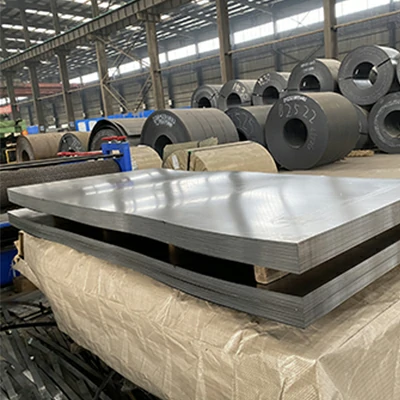

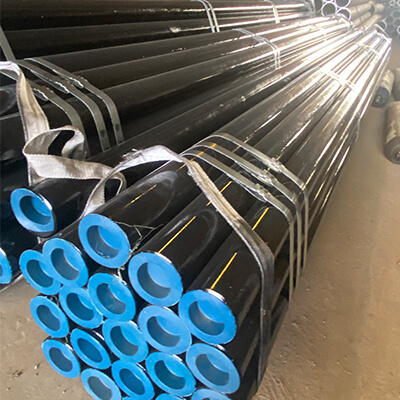

TOPERGAL as one of leading of China steel pipe suppliers, our company devote to supply the high-quality steel products to worldwide customers. These products include various steel plates and many kinds of steel pipes. But today, i want to introduce a almighty steel pipe to you. You may be curious which kind of steel pipe is almighty little prince. The answer is seamless pipe. Of course, the seamless pipe is worthy of this title.

The introduction of the seamless pipes.

Seamless steel pipes are cylindrical tubes made from solid steel billets without any welding joints or seams. They are manufactured through a process called seamless pipe manufacturing, which involves piercing a solid billet to create a hollow shell.

The advantage and application of the seamless pipe.

If you are a worker or a manger in the transport industry which need transport the petrol or the gas, you certainly know that there will generate high pressure in the ways of the transporting.

Then, due to seamless pipes’ homogeneous structure without weld seams, the seamless pipes are typically stronger than other pipes. And for this reason, it suit these places where need to endure the high press without breaking when be used.

Except the high strength and durability, it can also resist the corrosion well. Its construct decide it can highly reduce the the risk of corrosion along the pipe’s length. Especially when we need the pipe stay in the corrosive environments. Certainly, the galvanized steel pipes also have high corrosion resistance. But the galvanized steel pipes not have the same high stress resistance as the seamless. Of course, the galvanized steel pipes have lower price than the seamless pipes.we can choose the most suitable pips for us according the price, application ways and other aspects.

Then the seamless pipes have improved Flow Characteristics. Compared with welded pipes with internal weld seams, they have smoother internal surfaces. There have no doubt that the smoother internal surfaces can result in better flow rates and reduce frictional losses. Except can d that, the external surface of the seamless pipes also is smooth which is desirable in architectural and decorative applications.

Using the seamless pipes in many applications, we can reduce the cost of maintaining. The absence of weld seams reduces the likelihood of weak points where cracks or leaks could develop, lowering maintenance requirements and operating costs over the pipe’s life-cycle.

The specific production process of the seamless pipes.

- Steel Billet Preparation: In this step, our company always choose the high-quality steel billets or solid cylindrical bars. And we will accord the intended application and requirements of customers to select the specific steel billets.

- Heating: In this step, the worker will heat the steel billets into to a high temperature in a furnace. In this way, the steel billets can be more malleable and suitable for further processing. This process also called as billet heating. But you may can not understand the meaning of this step. We need to know that the step can help in reducing the risk of cracking during subsequent forming operations.

- Piercing: Once the steel billets heat to the appropriate temperature, the billets are pierced with a mandrel or piercing plug to create a hollow shell. This piercing operation is typically performed using a piercing mill or rotary piercing machine, where the billet is rotated while a piercing tool penetrates through its center, forming the initial hollow tube.

- Rolling: After piercing, the hollow shell undergoes further rolling processes to achieve the desired diameter, thickness, and length.

Sizing and Finishing:

Once the pipe reaches its final dimensions, it may undergo additional sizing and finishing operations to improve its surface finish, dimensional accuracy, and mechanical properties. These operations may include cold drawing, cold rolling, or other specialized processes to achieve the desired specifications.

- Heat Treatment: This step will depend on the steel grade and application requirements to complete. The ways include annealing, quenching, or tempering. After this step, the mechanical properties of the pipes can improve highly.

- Testing and Inspection: Through the production process, the worker will test the seamless pipes rigorously. To ensure the pipes can meet quality standards and specifications.

Our company has many high-quality steel pipe for sale. Such as the welded steel pipe, galvanized steel and seamless steel pipe. if you have the idea of buying these pipes, you can contract us. We are hoping the cooperation with you.