|

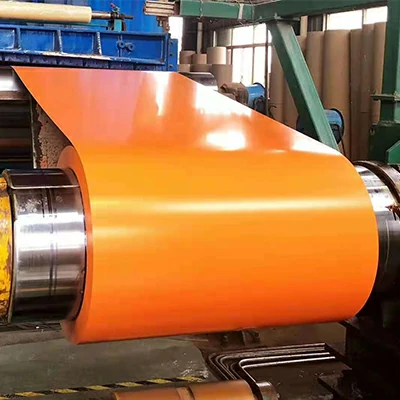

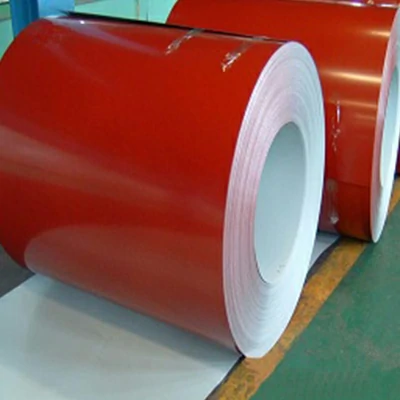

Product name

|

Ppgi Galvanized Steel Coil |

|

Stansard

|

AISI,ASTM,BS,DIN,GB,JIS

|

|

Material Grade

|

SGCC/CGCC/DX51D+Z

|

|

Surface Treament

|

Coated

|

|

Coating Material

|

PE,SMP,HDP,PVDF

|

|

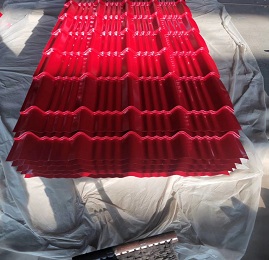

Color

|

All RAL colors or customers sampels color

|

|

Top Coating Thickness

|

15μm-25μm

|

|

Back Coated Thickness

|

5μm-20μm

|

|

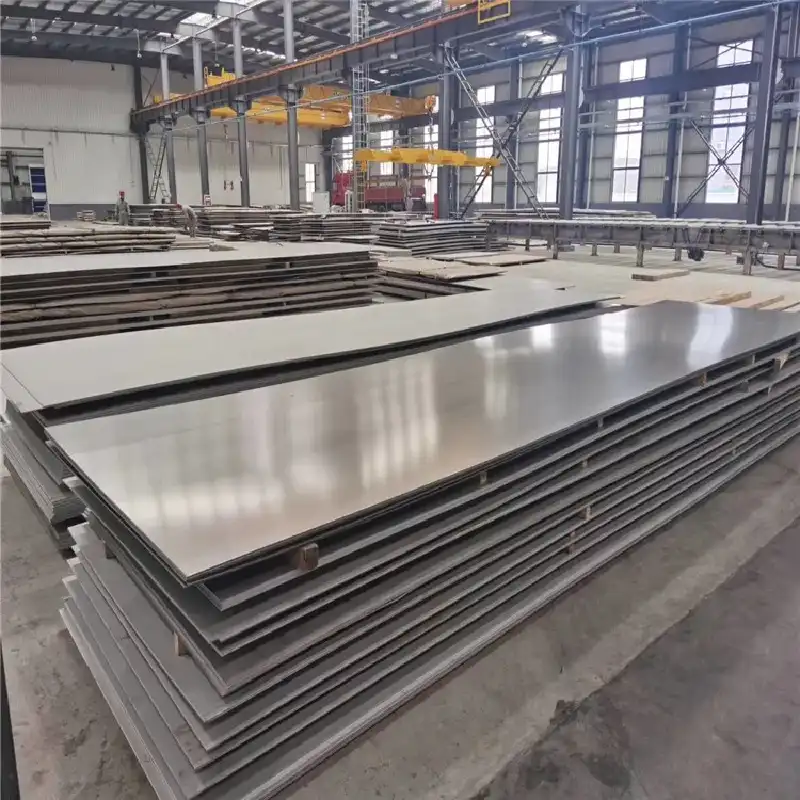

Thickness

|

0.12-1.20mm

|

|

Width

|

600-1500mm

|

|

Coil ID

|

508/610mm

|

China pipe manufacturers can meet any of your needs. We treat all inquiries and concerns about ppgi galvanized steel coil as incomparable. We carefully resolve your needs and create each product with ingenuity. We strive to give you not only high-quality products, but also peace of mind and satisfaction.For sheet steel coil each customer question highlights trust in our fuels our continual innovation.